Premier Engineering Products, are a leading organisation engaged in the design, engineering and manufacturing of various types of industrial dryers such as conveyor

dryers, tray dryers & batch type dryers in Kerala, India, since the year 1970. PREMIER DRYERS is one of our popular products.

![]()

Applications

For hygienic and cost-effective drying of various products in large quantities on commercial basis. Our dryers can be used for drying Coconuts, Desiccated coconut, Copra, Coconut gratings for VCO, Ginger, Turmeric, Pepper, Sliced vegetables (onions, garlic etc), Sliced fruits (pineapples, mangoes etc.), Grapes, Noodles, Fish, Shrimps and shrimp heads, Crumb rubber, Chemicals etc.

About Us

Established in the year 1970, Premier Engineering Products has been dedicated to designing and manufacturing various types of Industrial Drying machines like

Industrial Dryers, Conveyor Dryers, Tunnel Dryers, Batch type Dryers, Tray Dryers, Multiband Conveyor Dryer, Tilting Louver type Dryer, and Tower type Dryer,

Rotating shaft dryers etc.

Premier Engineering Products are the pioneers who had designed and developed indirect heated batch type copra dryers in India in the year 1970. More than 75%

of the Copra Dryers operating in India are manufactured and supplied by us. We have shown tremendous growth potential as a result of maintaining the most exacting

international standards and delivering high quality products at low cost, on time.

Our range of products are technology driven and meets the customer specifications. Owing to this we have become a strong contender with domestic and

international market for our precision products. We also export our product to other Asian Countries like Sri Lanka, Indonesia, Fiji, Nigeria, Gunia

Bissaue etc. Our Dryers are an ideal cost-effective solution for your drying needs as their quality is high and price low.

Infrastructure

The in-house infrastructure & experienced management helps Premier Dryers to offer world class products to its customers. We have a highly motivated team of engineers continuous effort to upgrade technology and adopt new technology to meet the challenges in the quality and costs are always on. We always strive for total customer satisfaction by continuously improving quality in order to achieve zero defect product.

Products

We manufacture and export the following types of Dryers:

- Multiband Dryer

- Tunnel Dryer

- Tower Dryer

- Tilting Louvre Dryer

- Batch Dryer

- Tray Dryer

- Copra Dryer

- Agro Dryer

- Industrial Dryer

- Desiccated Coconut Dryer

- Crumb Rubber Dryer

- Continuous Production Dryer

- Dehydration Machines

- Processing Machinery

Multi band Conveyor Dryer

This is a continuous production dryer with more than 2 conveyors inside the Tunnel. This is used for drying large quantity wet granular or sliced materials. Wet material fed at one end is obtained as dried material at the other end. The slats for the conveyor are usually made with stainless steel perforated sheets. Hot air is blown as through flow so that drying is fast and uniform. This type of Dryer is used for making good quality desiccated coconut powder (DC) and other high value items like sliced vegetables and fruits.

Tunnel Dryer

Tunnel type dryer is a continuous dryer, for processing wet solid materials. It is used for processing sliced vegetables, fruits, coconuts (for copra), rubber (for making crumb rubber) etc. Materials are fed in trays fixed in trolleys or in boxes with perforated sheet bottom. Trucks which moves inside the tunnel on rails from feeding end to the delivery end. Dried materials are obtained at the delivery end. Hot air is blown as through flow or concurrent flow or as counter flow according to the particular design.

Tower Dryer

Tower Dryers are used for drying free flowing wet materials like coffee seeds, pepper, grains etc. In side the tower there are inverted SS perforated sheet troughs. Material is fed at the top and flows down by gravity through the various rows of inverted troughs in a zigzag manner.The hot air is blown from bottom to top through the wet materials and the dried materials are obtained at the bottom of the dryer.

Tilting Louver Dryer

Tilting Louver Dryer is ideal for drying large quantity wet solid products which are to be overturned or mixed while drying is in progress. This is a multistage multy chamber dryer. The drying chambers can be of all steel construction or chamber in brick and cement construction. There can be 1,2, or 3 vetical steges seperated by tilting louvers. The drying will there for be uniform and fast. This dryer is ideal for fast and economic drying of ginger, cashew nuts, betel nuts etc.

Copra Dryer

Copra (Batch type) dryers are used for drying solid wet materials in one lot as a batch. Wet materials are loaded in a chamber over a platform having perforated sheet or weld mesh bottom to permit easy flow of hot air through materials. The hot air is blown into the plenum chamber below the platform by the powerful blower of the hot air generator and it passes through the wet materials extracting moisture from it. The moisture escapes through the opening on the top of chamber. Batch type dryers are very popular in India for making high quality edible white copra from well matured coconuts. It is approved by the Coconut Development Board of India. The copra making time is reduced to 24 hours of drying instead of usual 5 or 6 days by sun drying - The fuel used for drying can be coconut shell which is a by product in copra making or any other normal fuel like oil, gas, electricity, steam etc. As the hot air generator of dryer has a heat exchanger, it removes smoke and flue gas and only pure hot air is used for drying. Hence the quality of dried product is very high.

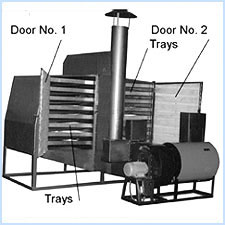

Tray Dryer

Tray Dryers are used for drying small and medium quantity materials. The materials are held in SS Trays with SS net or perforated sheet bottom. Hot air is blown through the material in up and down directions alternately, with the help of a special reversing flow valve. The drying will be fast and more uniform. The heating can be Electric or Steam or LPG. The outer body, doors etc. are with double walled insulated MS panel duly painted. Automatic temperature control is provided for each dryers.

Clients

We serve a wide variety of customers with a strong client base. Well established names of the industry prefer to work with us because of our credentials of consistently delivering high quality products, on time at competitive price.

Contact Us

Address

Premier Engineering Products, 3rd Floor, CRC Building, M.G. Road, Pallimukku, Kochi - 682 016 , Kerala (INDIA)

Phone

+(91)-(484)-2354841

Mobile

+(91)- 9847228055

Fax

+(91)-(484)- 2354841

Email

,

Contact Person

Mr. A.V. Varghese / Mr. Sunil

Built with Web Standards by Arun Kombiyil